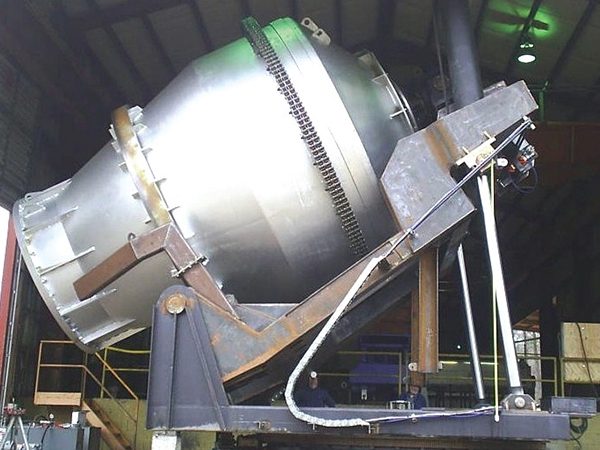

Rotary Furnace

- Drosses

- Mixed scrap often with contamination (tense, taint, tabor etc)

- Turnings / aluminium extrusion/ chips

- UBC

- Scrap contaminated with iron and steel inclusions

The rotary furnace range combines advanced melting technology, process control and high quality engineering. It is aimed primarily at recycling applications. The advantages and flexibility of the tilting rotary furnace continues to deliver savings and efficiencies throughout the aluminum processing industry.

It delivers outstanding energy savings and increases productivity as a bulk melter for die-casting applications. For melting mixed, contaminated scrap including oxidised materials such as dross, the combination of low energy, high metal recovery and flexibility of feedstock, have shown the tilting rotary furnace to be a class leader.

Crucible Furnaces

Crucible furnaces are one of the oldest and simplest types of melting unit used in the foundry. The furnaces uses a refractory crucible which contains the metal charge. The charge is heated via conduction of heat through the walls of the crucible. The heating fuel is typically coke, oil, gas or electricity. Crucible melting is commonly used where small batches of low melting point alloy are required. The capital outlay of these furnaces makes them atractive to small non-ferrous foundries.

Crucible furnaces are typically classified according to the method of removing the metal from the crucible:

Tilting furnace, in which the molten metal is transferred to the mould or ladle by mechanically tilting the crucible and furnace body.

Lift-out furnace, in which the crucible and molten metal are removed from the furnace body for direct pouring into the mould.

Bale-out furnace, in which the metal is ladled from the crucible to the mould.

Material analysis division

- SPECTROMAXx LMX07 Spectrometers

- Continuous monitoring of critical-to system components

- Identification and flagging of component maladjustment, degradation and failure

- Notification of local SPECTRO service for proactive support

- AMECARE M2M keeps SPECTRO

- Decreased risk of breakdown

- Faster support response

- Reduced repair times

Pollution System

We use industrial air pollution control, emission abatement and energy recovery systems. We design, manufacture, service and install thermal and catalytic oxidation technologies as well as heat recovery systems for a variety of applications and industries.

With an emphasis on engineering and problem solving, our goal is to provide solutions today that help customers remain profitable tomorrow.